Thermal cleaning systems remove polymers, plastic additives and recyclates from machine parts. Effective, safe and fast cleaning service also at the German equipment manufacturer’s site in Neukirchen-Vluyn

Compounding and plastics recycling are the central topics of the second Compounding World Expo in Essen. As a specialist for thermal cleaning systems, Schwing Technologies will be exhibiting at Europe’s leading trade event for plastics processing on September 29th and 30th of 2021. At booth A 815, the experts from the German machine manufacturer will provide information on the special advantages of their thermal cleaning technology. Typical application for the systems is the cleaning of plastics from tools and machine parts. In the compounding and recycling industry, these include in particular pelletizing dies and discs as well as die plates, extruder screws, screens and filter discs. With Schwing’s environmentally friendly, energy-efficient and effective systems, all polymers, plastic additives and recyclates can be removed quickly, safely and cost-effectively.

Cleaning solutions for individual needs

Three different systems from Schwing are available for this purpose. With the user-friendly and precisely controllable systems as well as further post-treatment devices, Schwing takes into account the individual needs and the variety of machine parts used in the industry:

– Pelletizing dies, extruder screws, screw elements, laser filters and filter discs as well as all plastics: cleaning by means of thermal vacuum pyrolysis in VacuClean and VacuClean COMPACT systems.

– Large tooling, e.g. large extrusion dies, and all halogen-free plastics: cleaning by means of thermal pyrolysis in MAXICLEAN systems.

– Hot runner manifolds, breaker plates, screw elements, etc., and for all polymers, including high-temperature plastics such as LCP, PEI, PPS or PI: cleaning using fluidized bed technology in InnovaClean systems.

There are numerous benefits for users in plastics processing and recycling, knows Virgilio Perez Guembe, Head of Sales at Schwing: “The use of our thermal cleaning systems significantly increases machine availability. This in turn minimizes interruptions, reduces costs and increases the productivity of our customers.”

Cleaning service in Germany and worldwide distribution

Schwing sells its technology solutions and equipment all over the world. In Germany, thermal cleaning is also offered as a service. Schwing also invites interested parties and customers to test cleaning results at the company headquarters in Neukirchen-Vluyn in the Lower Rhine region. In doing so, the equipment manufacturer is constantly developing the optimal efficiency of its systems and adapting the cleaning processes of innovative materials and new machine designs at an early stage.

Related Files

Schwing Technologies at Compounding World Expo 2021 (en) 1,023 KB

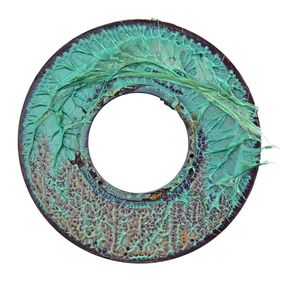

Laser filters can be quickly and safely freed of plastic residues with the aid of thermal vacuum pyrolysis. Here before and after cleaning in a VacuClean system Photo credit: SCHWING Technologies

The use of thermal cleaning to remove plastics from machine parts, such as pelletizer knives, significantly increases machine availability, reduces costs and increases productivity. Here before and after cleaning in a VacuClean system