InnovaClean Fluidized Bed System

InnovaClean is a compact, environmentally and user friendly fluidized bed pyrolysis system, which removes all polymers (even halogenated materials like PVC and PTFE) quickly and reliably from small and medium-size components and tooling.

-

Very fast residue-free cleaning in only a single process step

-

Flexible reliable cleaning of assembled and disassembled tools

-

Effective and environmentally compatible removal of ALL plastics

-

Increased lifetime of tooling and reduced machine downtimes

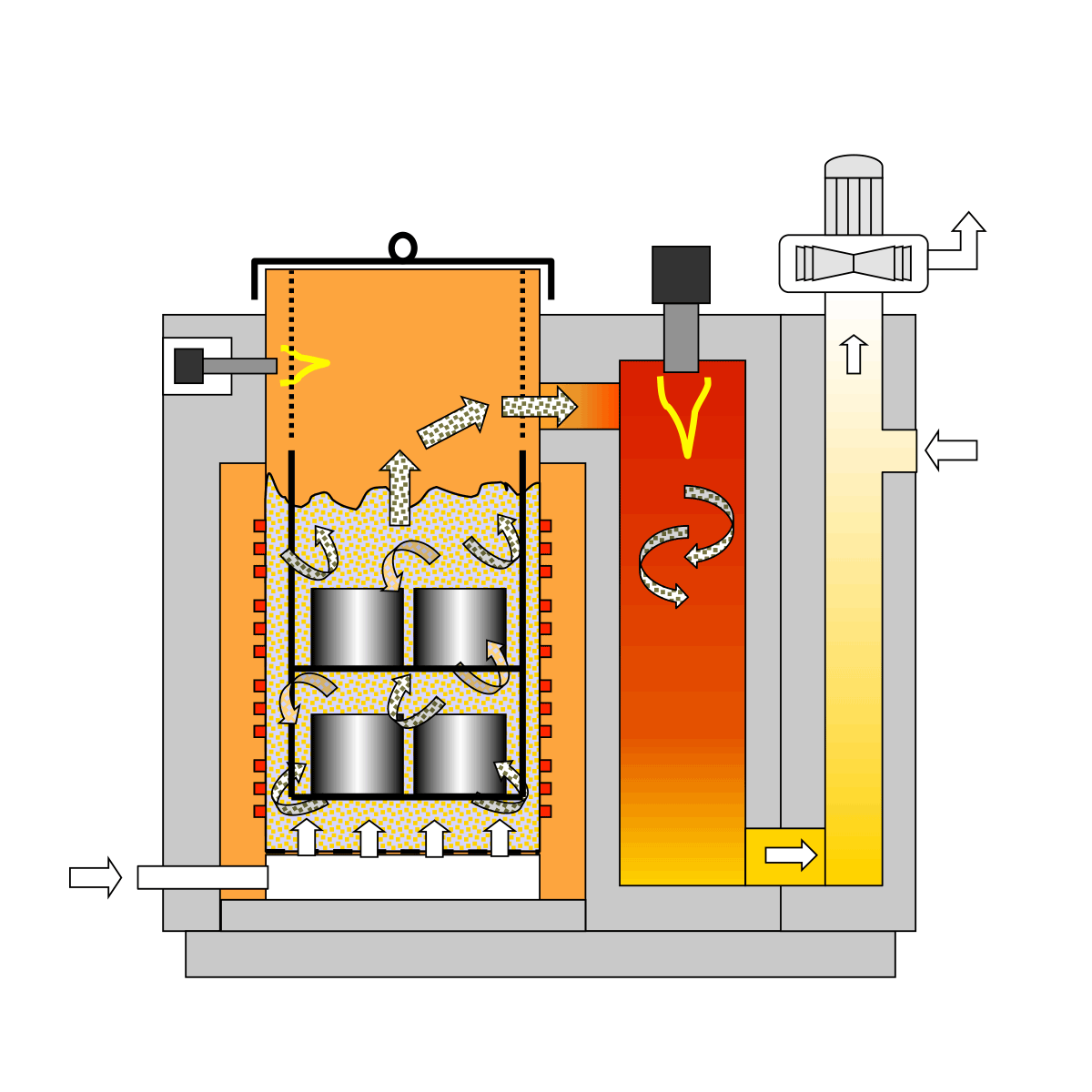

InnovaClean 2448-INB with Integrated Afterburner

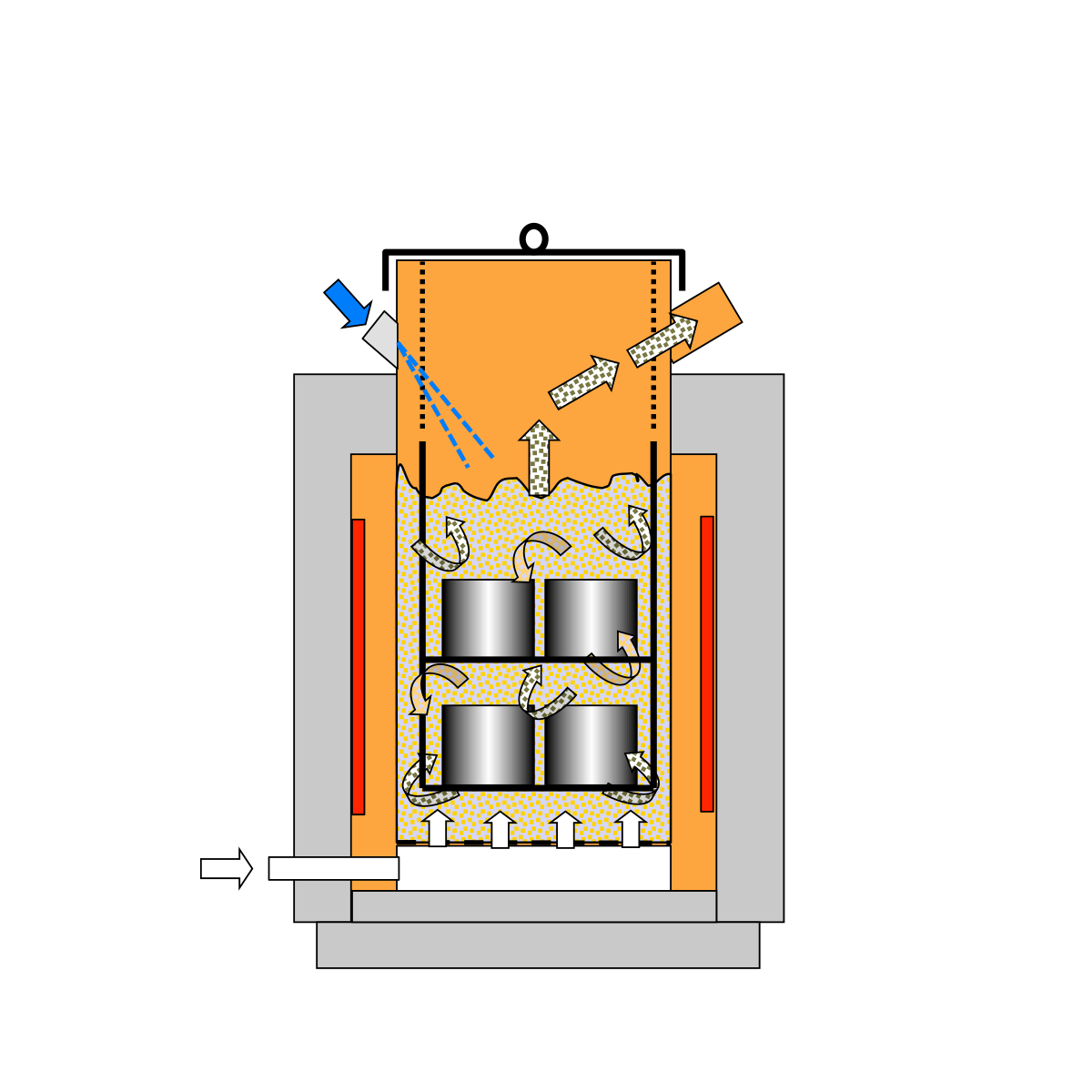

InnovaClean ECO 3-INB with Integrated Afterburner

Cleaning Process

InnovaClean fluidized bed system eliminates any polymer without residues within one to four hours, for example, from injection molding nozzles and die plates. Slightly longer cleaning times are required for spin nozzles, spin packs, static mixers, assembled pumps, backflow preventers, hot runner manifolds, and many other components.

Operating Principle for InnovaClean System

The precisely controllable cleaning process of InnovaClean utilizes heat transfer of a fluidized bed of THERMCLEAN sand. Tooling to be cleaned is freed from plastic quickly and without mechanical or thermal interference at pyrolysis temperatures from 850 to 1,000° F.

InnovaClean increases tool life and helps significantly reduce machine downtimes.

Off-Gas Handling

Upon request, InnovaClean can be equipped with a thermal afterburner or off-gas scrubber for the elimination of pyrolysis gases. Afterburners and scrubbers are integrated into the same system housing or may be set up as ancillary items.