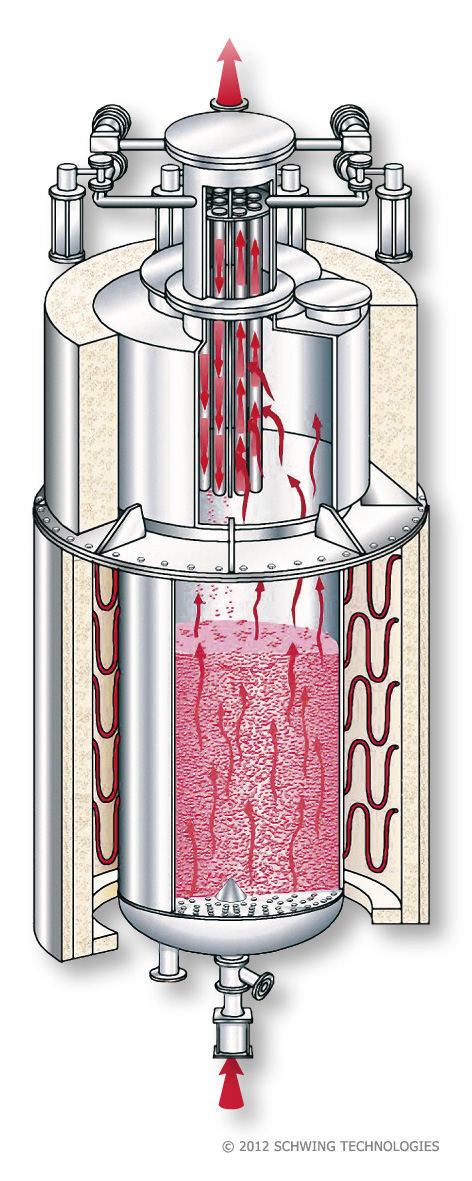

Fluidized Bed Powder Processing Systems

SCHWING Technologies provides solutions for fine particle treatment with our Fluidized Bed Reactors (FBR). Our systems are appropriate for a wide range of applications, where process atmosphere and temperature uniformity are crucial to producing materials of consistent quality. SCHWING FBRs provide excellent heat transfer and maximum gas-solid contact to facilitate numerous thermochemical reactions. Around the world, our customers appreciate the simplicity, reliability, and low maintenance of the fluidized bed system. SCHWING’s pilot plant is highly flexible for process development—providing feasibility and optimization trials.

Controlled Atmospheres for Gas-Solids Reactions

- calcining / tempering (e.g. air, N2)

- oxidizing / reducing (e.g. O2, CH4, H2)

- CVD / surface modifications (e.g. C2H4, HCl)

Wide Applications for powders and granules

- from 1 µm to 5 mm

Temperature Uniformity and Range

- up to 1200 °C (2200 °F)

- ± 2 °C (± 4 °F)

Hot industries / applications

- Catalyst activation / regeneration

- Battery materials

- Energy storage

- Surface modification

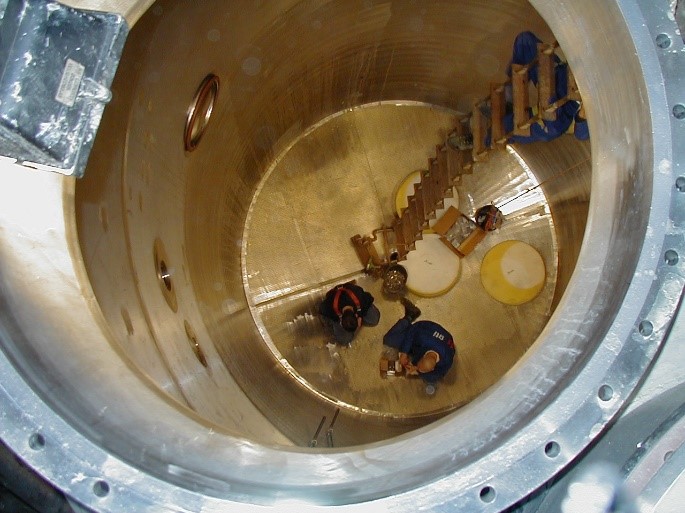

SCHWING Pilot Plant

Bench and pilot scale reactors offering flexible process temperatures profiles and process gas capabilities

- full piloting for batch and continuous processes

- highly flexible process gas / atmospheres

- from 5 L to 150 L

- environmentally responsible atmosphere controls

- up to 1200 °C

- up to 15 barg (210 psig)

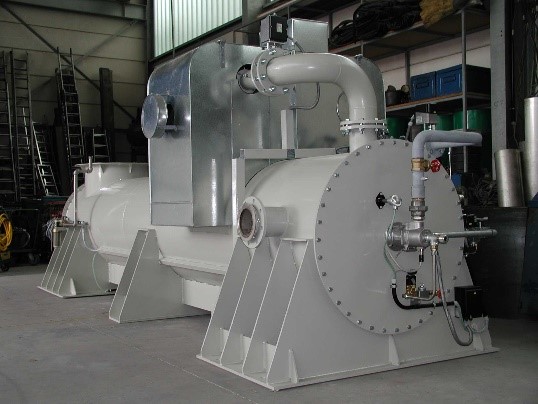

Standard & Custom Solutions

Systems designed and sized according to demand

- from 10 L to > 10 m3

- batch or continuous

- energy and environmentally optimized

- off-gas treatments: gas recycling, scrubbing, afterburning

Environmentally Responsible

Superior energy efficiency and gas utilization in dense-phase fluidized bed, combined with state of the art emissions controls

- optimal gas-solids contact

- no moving parts in FBR

- fine particle retention, no particulate emissions

- off gas thermal oxidation (afterburner)

- off gas wet scrubbing (e.g. caustic scrubber)

- gas recycling

Engineering & Service

Engineering services, on-site installations and startup assistance

- professional engineering services

- scale-up, environmental / haz-op analysis

- ease of startup and commissioning with SCHWING personnel

Applications

Catalyst Activation / Regeneration

Battery Materials

Energy Storage

Activated Carbon

Surface Modification