Fluidized Bed Heat Treatment Systems

SCHWING engineers and manufactures fluidized bed heat treatment systems. With this especially safe and time-efficient technology, metal or non-ferrous components are immersed into a retort filled with an inert, gas-fluidized oxide powder. The benefits of this fluidized bed process are its rapid heat transfer capabilities and excellent temperature uniformity. Partial heat treatment and hot-shaping are possible as well. Fluidized bed systems are also available as a quenching bath for gentle, fast cooling.

SCHWING heat treatment systems are heated indirectly via electric heaters or gas burners and can be used over a large temperature range from room temperature to 2,200° F. Components can be easily immersed in the fluidized bed, and in the shortest amount of time they can be:

- Preheated

- Annealed

- Austenitized

- Tempered

- Nitrided/nitrocarburized

- Oxidized

- Carburized/carbonitrided

Quenching and aging are also possible and offer major benefits for some industries. The emphases of the applications are energy-saving hardening of tools, low-warping or non-warping part treatment as well as the quick treatment of special parts.

Fluidized Bed of Heat Treatment System

HT 1050-3560 Fluidized Bed Heat Treatment System

Applications

Automotive

The benefits of SCHWING systems for the automotive industry comprise the great option of shaping and hardening, for example, body parts with the help of extremely uniform heat treatment. The fluidized bed has many advantages for ferrous and nonferrous metal castings, for example engine blocks or other components made of aluminum by high pressure die casting.

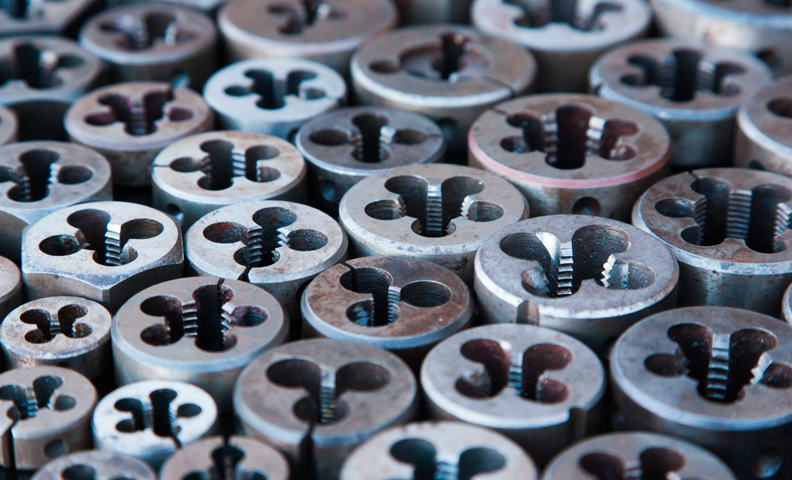

Tool & Dies

Tool steel can be heat treated economically using a fluidized bed furnace. Hardening is the most common heat treatment applied to tool steels. Many heat treatments are possible though. Since gases are used to fluidized the bed, any gaseous atmosphere can be used, and it can be changed in only a few minutes. This feature allows for multiple heat treating processes to be performed in the same furnace.

Springs

After manufacturing coil springs, stresses exist within the structure of the metal. These residual stresses can lead to defects and cracking, so stress must be relieved to maximize the elastic properties of the spring material. Fluidized bed heat treatment is particularly suitable for the rapid stress relief of small- and medium- sized coil springs.

Medical

Medical technology represents a high-precision industry governed by the highest quality standards. This applies also to the production and heat treatment. For example, stents, with their basic structure from stainless steel, require precise shaping. These life-saving medical products are often so small that their uniform treatment and shaping presents problems. With heat treatment processes from SCHWING, stable shape-setting is achieved easily and reliably.

Nitriding

Nitriding is a low-temperature surface treatment used to improve wear resistance, obtain high surface hardness, and improve resistance to corrosion. Nitrogen is introduced into the surface of a solid ferrous alloy by depositing a metal work piece into a heated fluidized bed that has sufficient nitrogenous gas, usually ammonia. The advantage the fluidized bed offers is a reduced cycle time because of its fast recovery and atmosphere composition changes.

Cooling

Fluidized bed technology is used for cooling of components and materials. Heat exchange takes place by passing a gas through a distributor plate which then flows through a bed of solids. Fluidized bed is used for quenching in larger volume tanks.