Testing in Fluidized Bed Heat Treatment Systems

The unique temperature uniformity of the SCHWING fluidized bed system facilitates an extremely precise and easy to reproduce high-temperature application, as is required, for example, for special thermo-chemical conversions of solid particles via reaction gases or for the calibration of temperature sensors and thermal instruments.

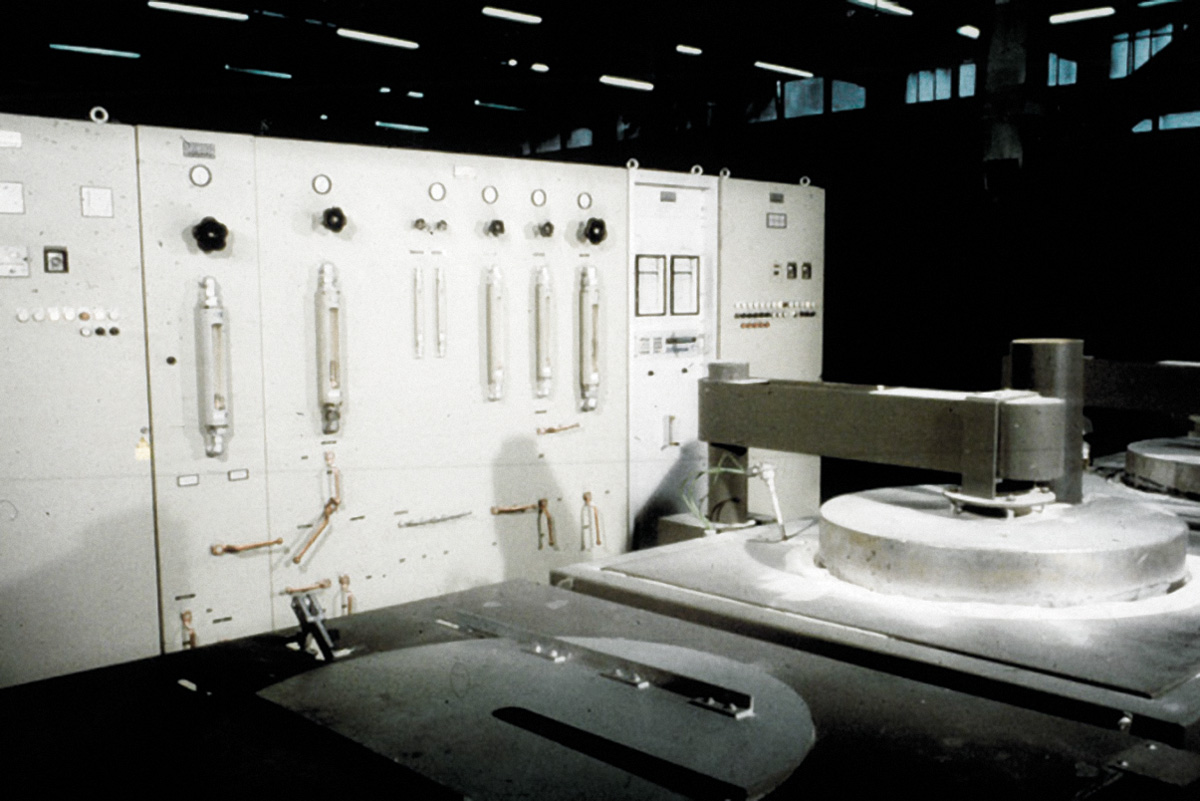

SCHWING has various lab equipment units and high-temperature fluidized bed systems with a volume up to 120 liters and temperatures up to 2,200° F available for heating, hardening, quenching, and surface treatment tests.

SCHWING Fluidized Bed Heat Treatment Systems

System and Process Consulting

The consulting and planning staff of SCHWING combines over 50 years of engineering and application experience in the engineering of high-temperature systems for heat treatment of materials as well as for thermo-chemical conversion processes up to 2,200° F. This experience is manifested in industry-specific consulting and implementation competency for the metal and automotive industries as well as other sectors with heavy emphasis on processing.

Know-how and the independence from specific technologies provide SCHWING with the unparalleled advantage of being able to offer the respective best and preferred device and system solutions, both economically and ecological, to any customer; this pays off especially with the development and realization of special heat treatment systems for innovative material concepts.

Development and Engineering

Comprehensive special knowledge and proven system solutions in heat treatment and the thermal processing of metal parts, especially high-temperature experience in fluidized bed process technology and the continuous improvement of the control and automation technology in regard to user comfort and environmental compatibility.

We are committed to finding the best and preferred solution for any customer request or production equipment in regard to the specific application, the material used and the respective production process – all based on state-of-the-art German engineering.