VacuClean System

VacuClean is an advanced vacuum pyrolysis system for removing plastic residues from critical machine tooling, dies, and filters. Depending on the system size, components to be cleaned, and polymer type, VacuClean removes polymer from tooling within 8 to 30 hours without impacting the parts thermally or mechanically. Integrated catalytic converter system ensures clean exhaust air and unpolluted waste water.

Front Loading Systems

- Ideal for blown film dies, spin packs, filter bundles

- Handles parts up to 66 inches in diameter and 27,500 pounds

VacuClean 1212

VacuClean 1713-XXL with Loading Table and Rollable Pallet

Top Loading Systems

- Ideal for nonwoven dies, extruder screws, barrels

- Handles lengths of up to 21 feet

VacuClean 154

VacuClean 254

VacuClean 454 with Open Lid

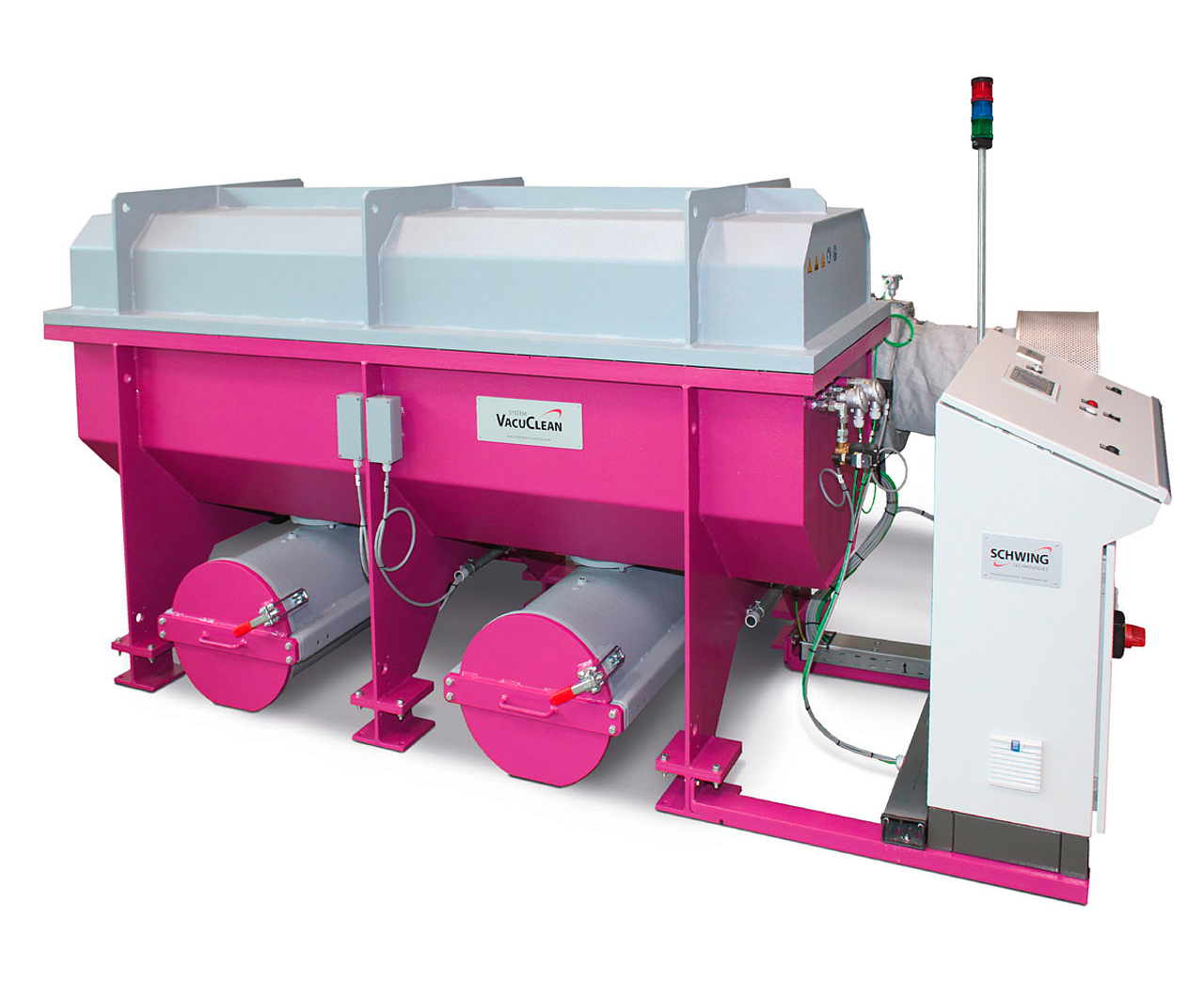

Compact System

- Best for small pelletizing dies, spinnerets, filter discs, injection molding nozzles

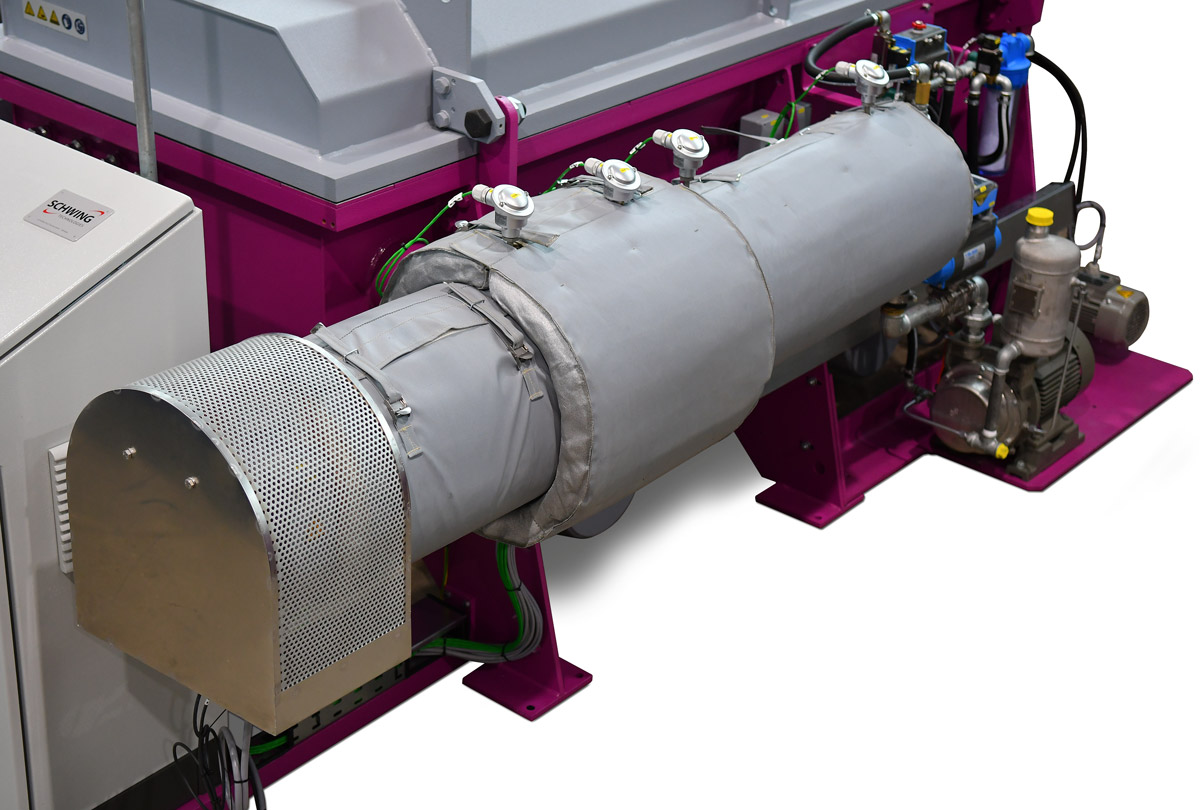

VacuClean Compact

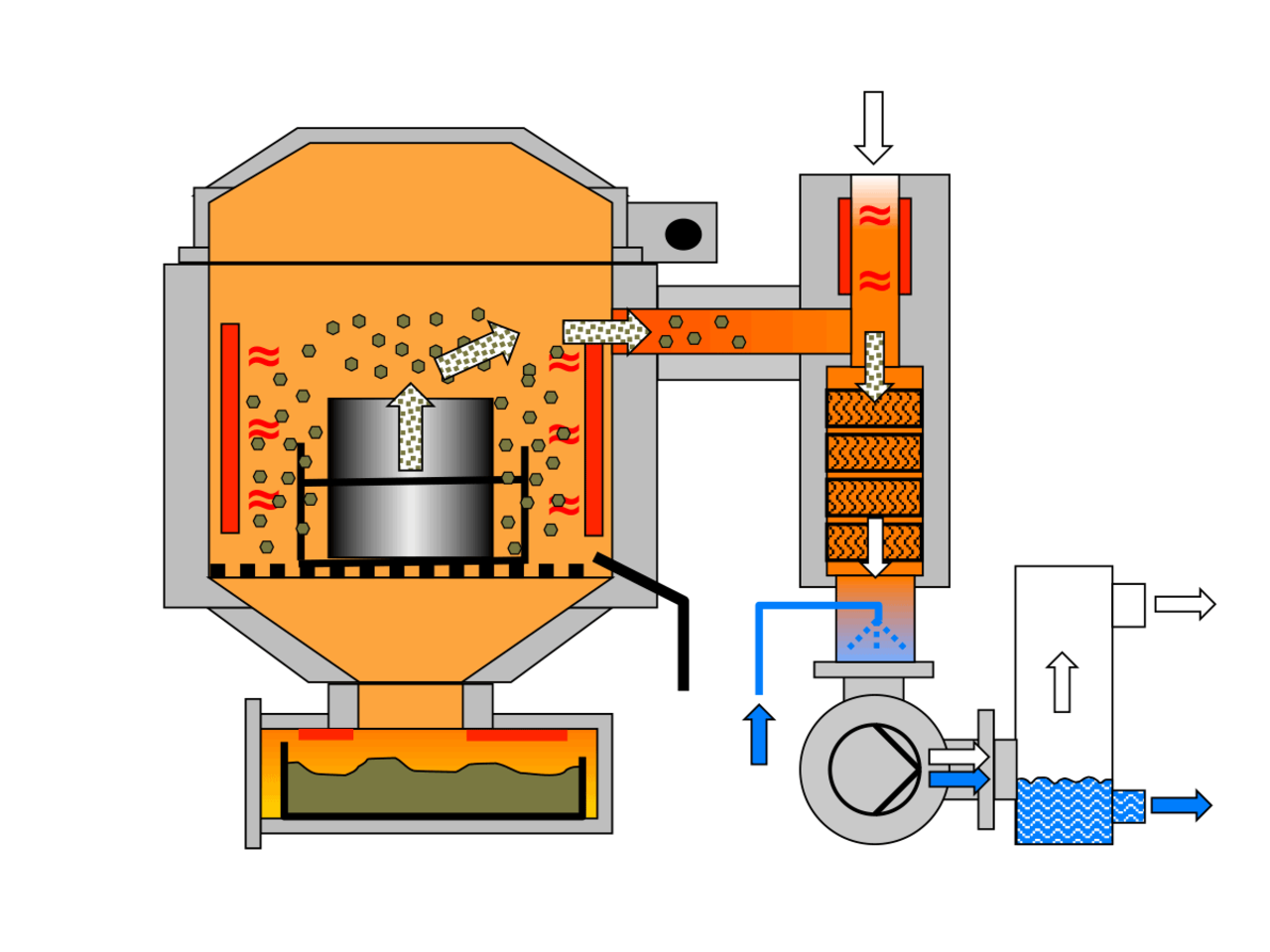

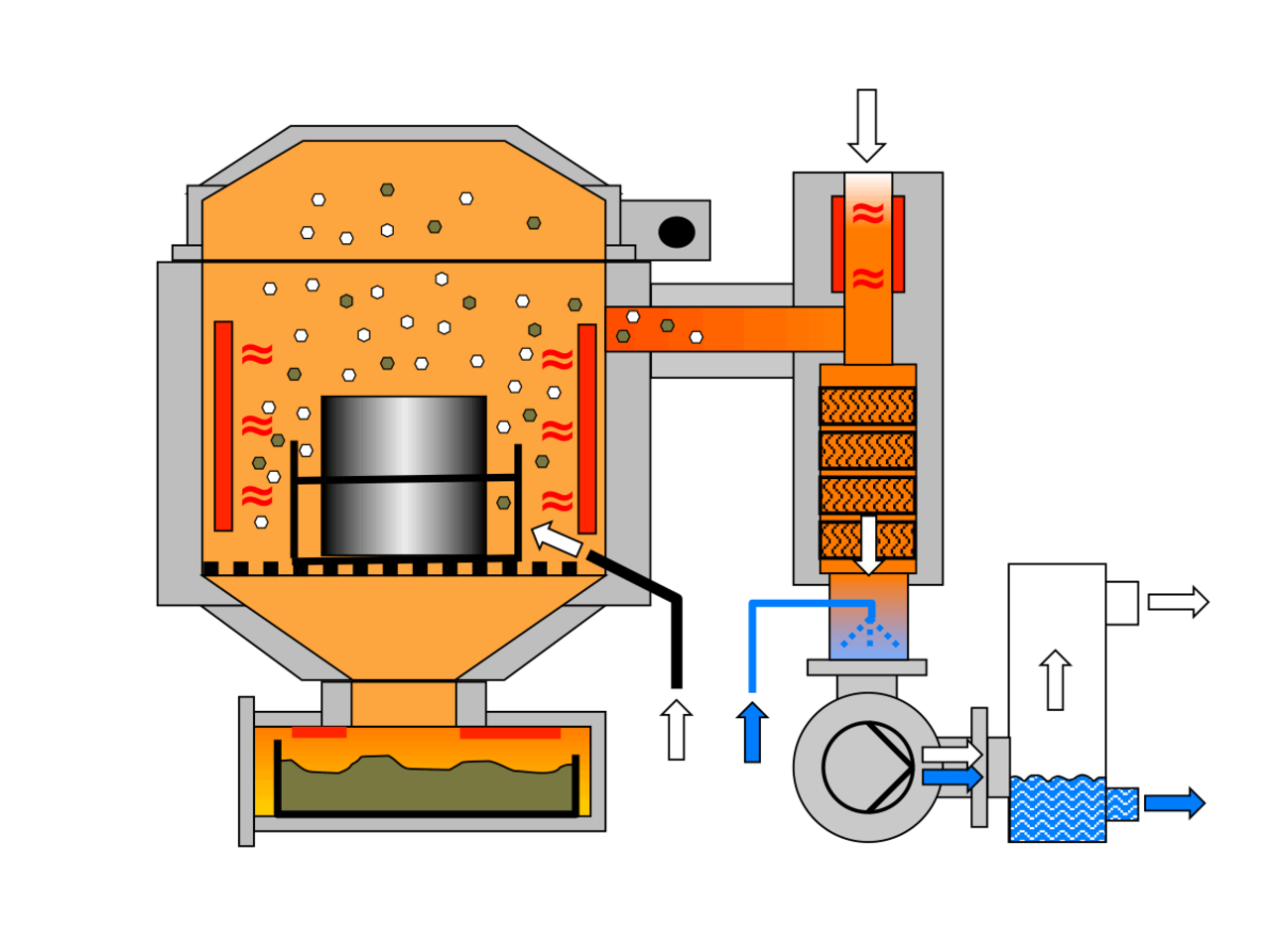

Operating Principle for VacuClean Compact

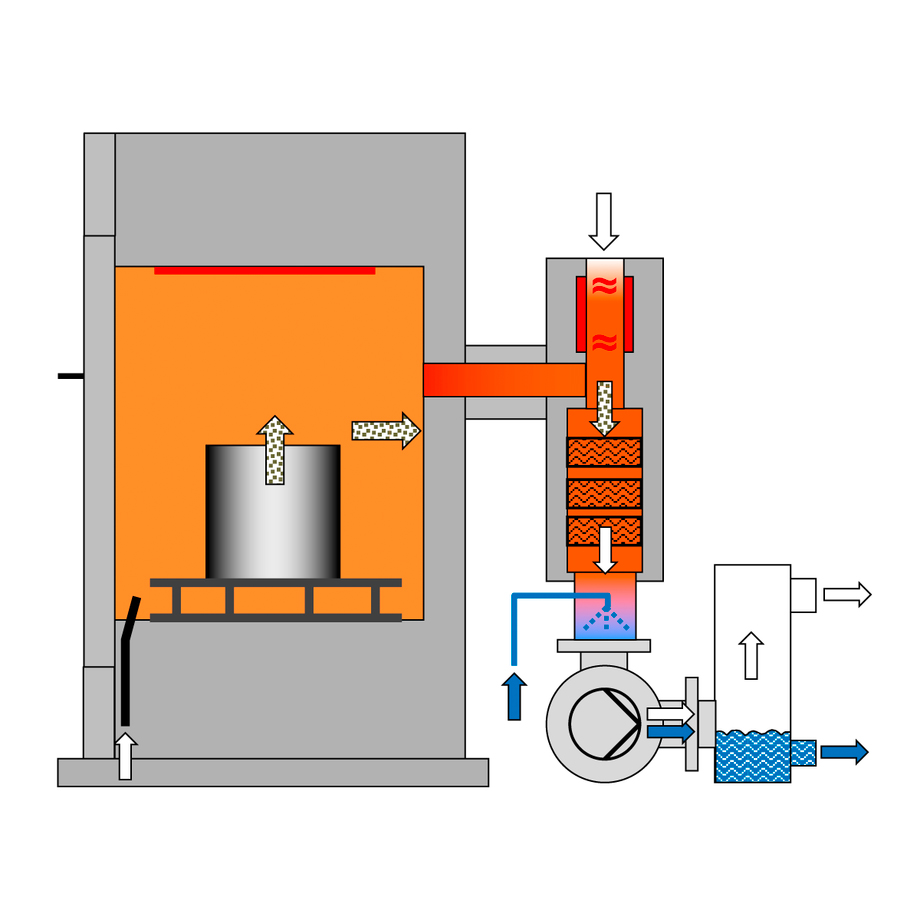

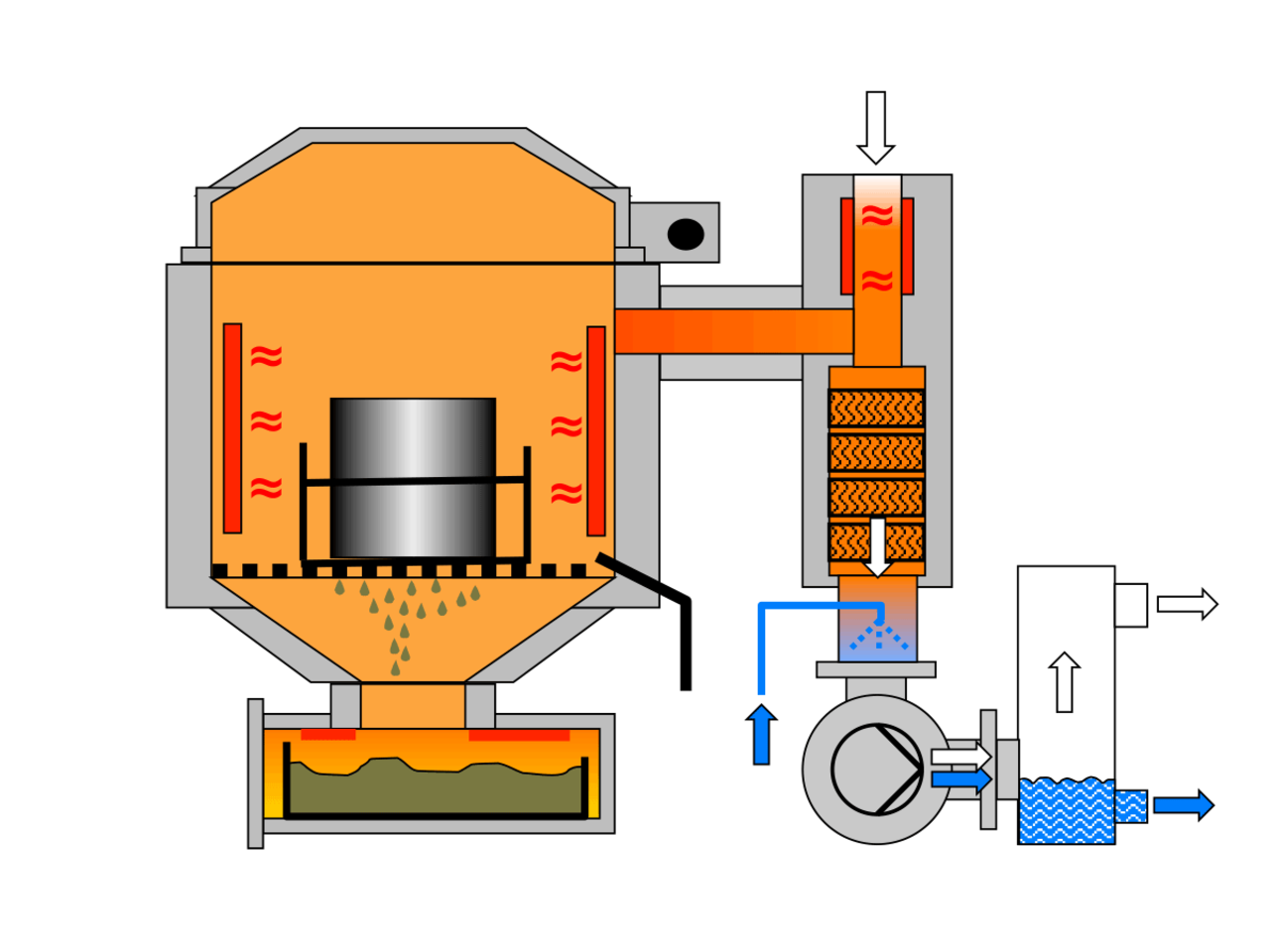

Cleaning Process

The fully automatic cleaning process of VacuClean takes place in an electrically heated vacuum cleaning chamber. The temperature of the component is measured directly on the surface of the component to be cleaned, which is initially heated slowly. A large amount of the adherent polymer melts now and drains off. The disintegration of the remaining polymer takes place at approx. 850° F. Remaining carbon is finally removed by adding air (oxidation). A sophisticated sensor system controls the cleaning process preventing the development of excess temperatures at all times. Inorganic residues can be easily removed through post-treatment, e.g. with compressed air.

(1) Melt-off under vacuum

(2) Vacuum pyrolysis phase

(3) Vacuum oxidation phase

Integrated Catalytic Converter

Integrated catalytic exhaust air cleaning system automatically controls the cleaning process, ensuring clean exhaust air and unpolluted waste water.